Sede legale

Via Carone 28, 25065

Lumezzane (BS), Italy

P.IVA 00585610983

C.F. 00889440178

Uffici e sede produttiva

Via Industriale 27

25070, Bione (BS), Italy

Tel. +39 0365 897024

GNALI ETTORE di Gnali Amelio S.r.l.

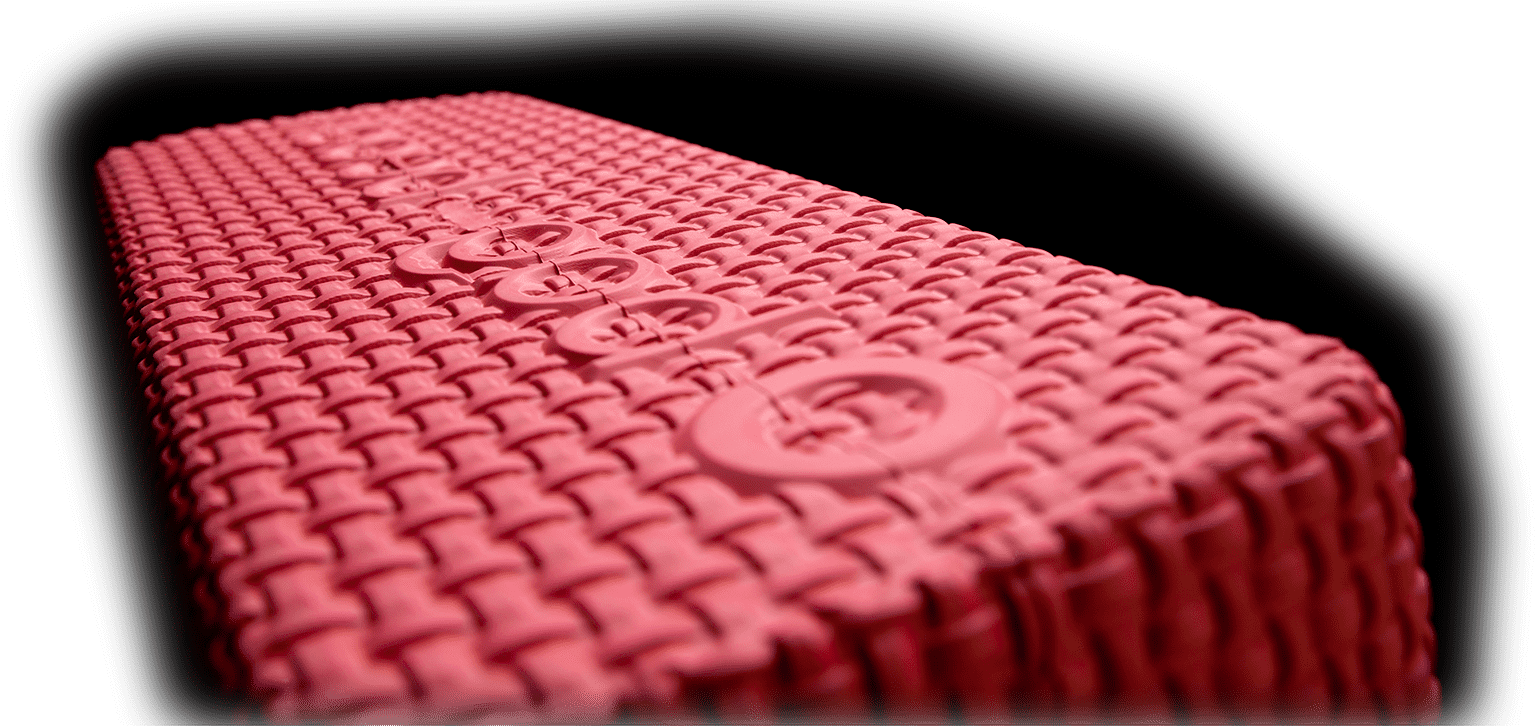

Gnali aims to redefine and expand the possibilities afforded by plastic moulding and offers its customers unprecedented opportunities for manufacturing their products in terms of use, materials, design and performance. To this end, the company makes available to every project its wealth of technical expertise, over half a century of experience in the industry, state-of-the-art technology and the inestimable “knowing how to do things well” of the company team. The customer will therefore find in Gnali not only an expert and reliable partner, but above all a powerful force able to turn their dreams into reality.

Gnali manufactures its products exclusively in Italy according to a strict product culture that includes the excellence of the materials, high specialisation, manufacturing precision, technology and several decades of know-how.

For the customer this translates into impeccable fabrication of the moulded product, with a very low error percentage and above all the ability to with tackle even the most complex projects with expertise and success.

The company always guarantees the highest quality moulded products, extremely precise and clean workmanship, virtually flawless. To such an extent it can be said that once the products have come out of the moulds and been subjected to minimal aesthetic cleaning, they are already finished to all effects (whether finished or part-finished items) and ready for the next phase of packaging or any assembly required with other components.

Gnali is actively committed to adhering to the principles of the most responsible and sustainable production methods, aware of the urgency of environmental issues. Over time various actions have been undertaken in this direction, which today allow the company to recycle 100% of the waste from its production processes.

All of the waste material deriving from EVA moulding is consigned to a specialised partner of the company, who recycles it and uses it again to make soundproofing insulation panels, thereby guaranteeing a new life to a material otherwise destined to be considered special waste and disposed of with a detrimental impact on the environment.

Gnali aims to redefine and expand the possibilities afforded by plastic moulding and offers its customers unprecedented opportunities for manufacturing their products in terms of use, materials, design and performance. To this end, the company makes available to every project its wealth of technical expertise, over half a century of experience in the industry, state-of-the-art technology and the inestimable “knowing how to do things well” of the company team. The customer will therefore find in Gnali not only an expert and reliable partner, but above all a powerful force able to turn their dreams into reality.

Gnali manufactures its products exclusively in Italy according to a strict product culture that includes the excellence of the materials, high specialisation, manufacturing precision, technology and several decades of know-how.

For the customer this translates into impeccable fabrication of the moulded product, with a very low error percentage and above all the ability to with tackle even the most complex projects with expertise and success.

The company always guarantees the highest quality moulded products, extremely precise and clean workmanship, virtually flawless. To such an extent it can be said that once the products have come out of the moulds and been subjected to minimal aesthetic cleaning, they are already finished to all effects (whether finished or part-finished items) and ready for the next phase of packaging or any assembly required with other components.

Gnali is actively committed to adhering to the principles of the most responsible and sustainable production methods, aware of the urgency of environmental issues. Over time various actions have been undertaken in this direction, which today allow the company to recycle 100% of the waste from its production processes.

All of the waste material deriving from EVA moulding is consigned to a specialised partner of the company, who recycles it and uses it again to make soundproofing insulation panels, thereby guaranteeing a new life to a material otherwise destined to be considered special waste and disposed of with a detrimental impact on the environment.

Sede legale

Via Carone 28, 25065

Lumezzane (BS), Italy

P.IVA 00585610983

C.F. 00889440178

Uffici e sede produttiva

Via Industriale 27

25070, Bione (BS), Italy

Tel. +39 0365 897024

GNALI ETTORE di Gnali Amelio S.r.l.

Reserved © 2024 All rights reserved –

Privacy Policy – Credits